How to Build a Diagnostic System of KPIs Using a Process View

by Stacey Barr |Back in the 1990s process thinking was all the rage. Organisations world-wide were identifying their core business processes, mapping and flowcharting and doing Six Sigma and Lean and BPR to ramp up business performance. Was it just a fad?

Or is there something more fundamentally important, particularly to mastering business performance, to process thinking?

Why put your attention on processes?

One very essential reason that we have corporations, businesses and other organisations in the first place, is that something needs to get done again and again for a particular group of stakeholders or customers.

This thing that needs to get done again and again—which might be roads being built in our cities, or illnesses being diagnosed and cured, or apples being available at the supermarket—happens through a process.

In other words, how work actually happens in our organisations and businesses is through a series of steps or activities that flow together as a process.

Here’s the kicker: how well our processes are designed directly determines how well we do the thing our organisation is supposed to do. Process performance directly impacts organisational or business performance.

Contrary to popular belief, it’s actually process performance that has the biggest impact on organisational and business success, not people performance.

So process performance is too important not to measure.

What do you measure about processes?

You’re not going to know what to measure about processes until you first figure out what your processes are, and what results they produce that most drive organisational success.

One of the best ways to figure out your processes is to start with your customers, and name the outputs you produce for them. Then for those outputs, map backwards to find the flows of activities and steps that produce those outputs. Flowchart all the way back to the very trigger that sets that output-producing process into action. Mostly it’s when the customer asks for your service or product.

Just imagine a company, let’s call them Shake The Tree Inc., that grows and packs apples for customers to buy at the supermarket. The output is clearly apples ready to eat! And the flow of activities in the apple producing process might, at a rather high level, involve:

- Take advance orders for apples from green grocers.

- Nurture and grow the apples throughout the season.

- Pick the apples when ripe.

- Pack the apples.

- Ship the apples to green grocers.

The first type of process measure is the Process Outcome Measure.

The outcomes that matter to Shake The Tree Inc. from this process might include things like green grocer satisfaction with apple quality, and earnings per tonne of apples.

They’d want to measure these, and we could call these measures Process Outcome Measures:

- Average Green Grocer Satisfaction = The monthly average satisfaction that green grocers, who purchased apples from us in the month, have overall with the quality of apples they received.

- Earnings Productivity = The average amount of revenue earned per tonne of apples picked.

The second type of process measure is the Process Output Measure.

Process outputs are the tangible or observable products of a process. They are are different to process outcomes: outputs are what we give to our customers, but outcomes are how these outputs benefit or impact on our customers.

The quality and quantity of our process outputs can directly influence the process outcomes. For Shake The Tree Inc., apples are their outputs. And specific qualities of the apples would lead them to identify Process Output measures like these:

- Damaged Apples = The percentage of apples customers receive that were unfit for sale.

- Apple Order Fulfilment = The percentage of customer ordered quantity that was delivered.

The third type of process measure is the In-Process Measure.

Each of the above broad steps in the process might impact the process outputs and outcomes. For example, Earnings Productivity would be impacted by the costs of fertilizing and pest control at step 2. The proportion of apples discarded (maybe because of worms or unsightly skin markings) at steps 3, 4 and 5 would also impact earnings per tonne of apples.

Shake The Tree Inc. would want to measure these too, to diagnose how they could improve earnings next year. We could call these measures In-Process Measures, since they measure the results of activities IN the process:

- Fertilization Costs = Total cost of purchasing and applying fertilizer to the apple crop.

- Pest Control Costs = Total cost of purchasing and applying pest-control to the apple crop.

- Discarded Apples = The percentage of the apple crop that was not sold to end customers.

In-process measures are the drivers of process outcome measures.

The great thing about using processes as the framework to identify your performance measures is that you build a natural diagnostic system of measures.

The measures of process results tell you how the process is going in general. But rarely do they tell you how to improve process performance. That’s where the in-process measures come into their own. They are measures that give you the clues about what to fix to improve performance. Nice.

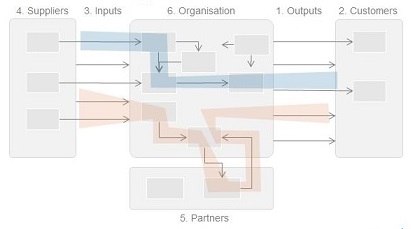

For PuMP users, you’d align Process Outcome and Output measures to the results in the blue layer of the Results Map. And then your In-Process Measures would align to the results in the orange layer of the Results Map.

TAKE ACTION:

Have a go at identifying and flow-charting just one of the business processes in your organisation or company. Notice how easy it is to identify results that could be important to measure.

Connect with Stacey

Haven’t found what you’re looking for? Want more information? Fill out the form below and I’ll get in touch with you as soon as possible.

167 Eagle Street,

Brisbane Qld 4000,

Australia

ACN: 129953635

Director: Stacey Barr